F.u.l.can supply circular saws in high speed steel (5% molybdenum content) suitable for cutting-off steels and alloys with tensile strength between 500 N/mm² and 800 N/mm². The saw blades are used on manual, semi-automatic and fully automatic sawing machines to cut tubes and pipes, open sections and solid sections up to 200 mm.

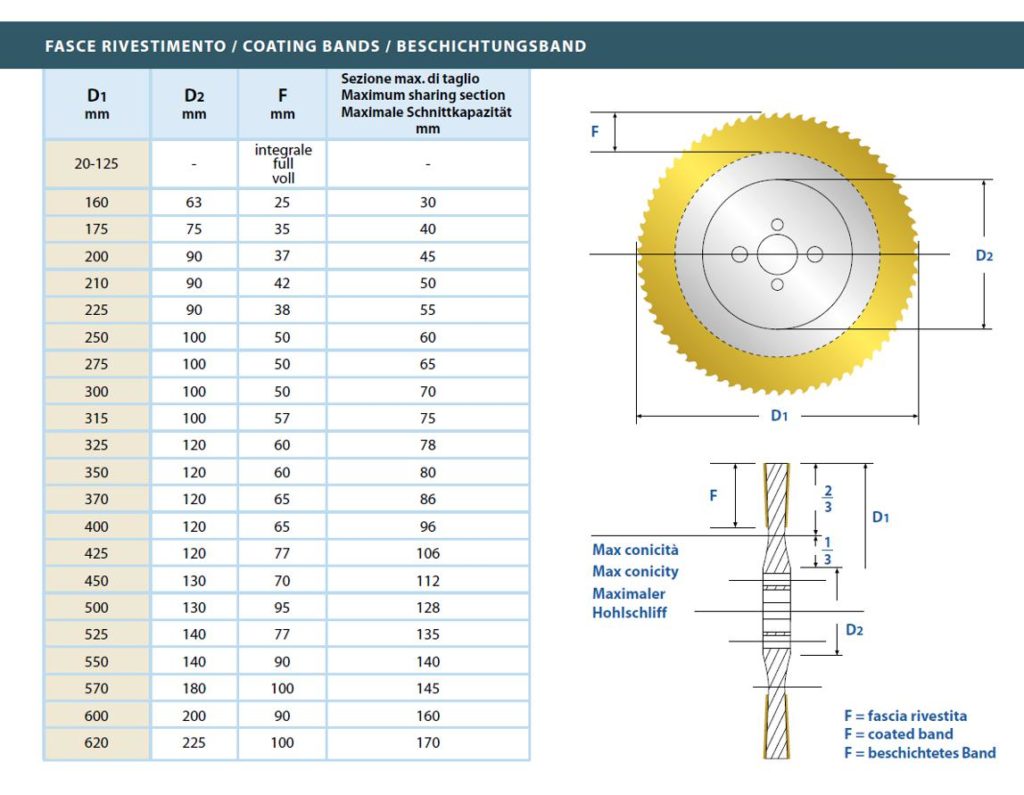

Our range goes from Ø 160 mm to Ø 620 mm, with thicknesses from a minimum of 1 mm to a maximum of 6 mm by variable increments, with tooth forms A – AW – B – BW – C – BR (chip breaker).

The standard execution of the whole range is HP-GRIND; we also supply CO² steam treated blades and PVD (Physical Vapour Deposition) coated ones.

HSS-DMo5

Circular saws in super high speed steel (5% cobalt content) suitable for cutting-off steels and alloys with tensile strength above 800 N/mm². The saw blades are used on semi-automatic and fully automatic sawing machines to cut tubes and pipes, open sections and solid sections up to 200 mm

TCT CIRCULAR SAW BLADES

HM carbide tipped circular saws suitable for cutting steel solids or profiles with big wall thickness.

The special patented tooth form allows these special blades to drastically reduce the cutting times and improves the surface finishing if used on the right machine.

Our range covers different diameters from 250 mm to 315 mm with a central bore of 32 and 4/9/50 pinholes or diameters from 360 to 460 mm with central bore 50 mm and 4/16/80 pinholes.

Also available with cermet toothing or TiN coated

FRICTION SAWS FOR CUTTING PIPE AND PROFILES

Julia produces friction saws for flying or static cutting of pipes and profiles in carbon steel such as ST37, ST52, etc., with tensile strength ranging from 300 and 600 N/mm².

Our friction saw blades are manufactured with two different materials: chrome-vanadium steel (80CrV2 or 1.2235) and wolframium-molibdenum (73WCrMoV2 or 1.2604).

Our available range encompasses all dimensions mounted on the most common macchines using the friction cutting technology, such as:

Abbey Etna, Dreistern, Mannesmann, Oto Mills, MTM, Vai Seuthe, TRM, Trennijaeger.

The friction saw blades, unlike cut-off circular saws (low RPM), run at a very high RPM, so generating in the cutting area very high temperatures bringing the material in plastic condition easing its cutting.

The cutting is performed in a dry condition and the blade is cooled off only after the cutting; this lubrication lengthens the blade life.