Inside Scarfing Tool

COMPLETE PNEUMATIC SYSTEM FOR INTERNAL WELDING BEAD REMOVAL

F.U.L. develops, builds and finally sells complete systems for welding bead removal, inside High Frequency welded tubes.

These plants have got innovative characteristic to be fully pneumatic.

The advantages obtainable using pneumatic systems, are summarized below:

- must be no change existing plant.

- no need for additional accessories

- no need for complicated settings

- less adjustment of the inside tool holder during start-up and during daily production.

- low cost of hard metal inserts.

- longer working-life of hard metal inserts

- Less “stop and go” of the mill

- Low production costs

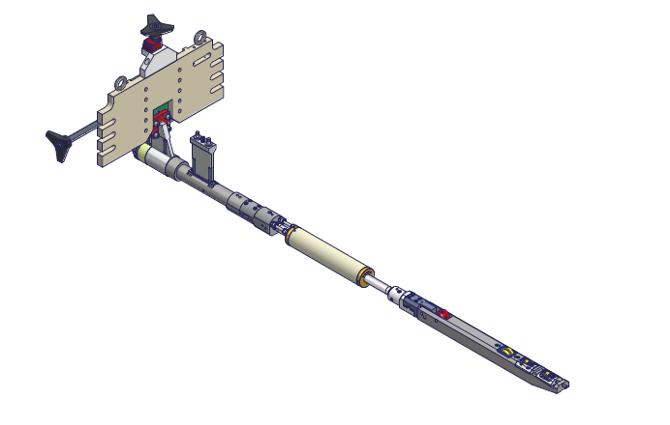

How does it work:

compressed air, introduced into tow bar fixed at the Mounting Unit, gives to the lower carriage a very high pressure so that cutting insert works on tube wall.

The cutting insert, placed on the opposite side (scarfing point), affects and simultaneously removes the welding bead

Maunting unit provides to adjust the whole system.

No further adjustment is necessary.

The cutting insert geometry allows a constant stock removal; it doesn’t care about wall thickness changing

According to our old experience developed in this specific market, and according to the customer production requirements, taking care with our customers,row materials and thicknesses of the tube to be produced, F.U.L. can design and develop, complete inside scarfing tools, adapted for every type of carbide insert as “cutting ring” or “nail shape”.

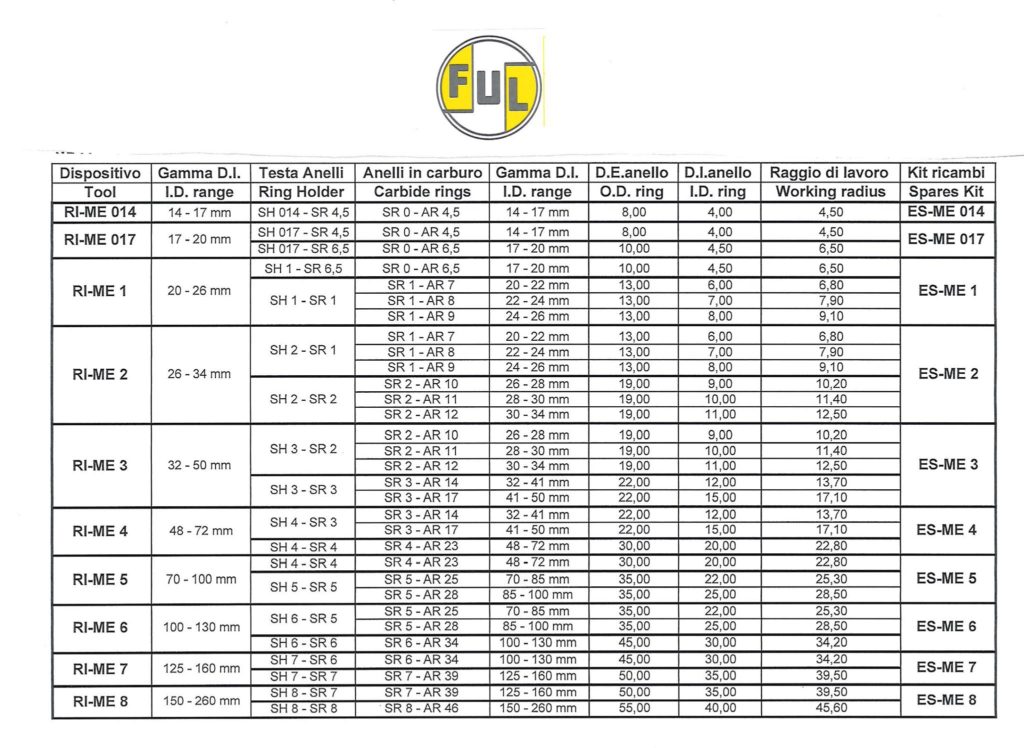

We can also supply the full range of mechanical RI-ME as follows: